Fleet Lithium offers high-performance lithium batteries to fit all major golf cart brands (E-Z-GO, Club Car, Yamaha, etc.) and system voltages (36V, 48V, 72V). Whether your cart is a classic 36V model or a modern 72V powerhouse, there's a Fleet Lithium pack designed as a drop-in upgrade. These lithium packs – with advanced integrated BMS – provide dramatically improved runtime, lighter weight, and zero maintenance compared to traditional lead-acid batteries. Below we outline battery compatibility by brand and model, key battery specifications, installation tips, and how Fleet Lithium compares to competitors.

Table of Contents:

Battery Compatibility by Brand

E-Z-GO Golf Carts (36V, 48V & 72V)

- Older 36V Models (TXT & Medalist up to early 2000s): These carts can shed hundreds of pounds by upgrading from six 6V lead-acid batteries to a single Fleet Lithium 36V 105Ah pack. The 36V (nominal ~38V) lithium offers equal voltage for compatibility and far greater runtime. It’s an ideal replacement in early TXT-series carts, delivering lighter weight and zero maintenance without altering the stock 36V system. Users will see improved acceleration due to the weight drop and higher sustained voltage under load, even if top speed remains controller-limited.

- 48V Models (TXT 48, RXV, Freedom): For the ubiquitous 48V E-Z-GO carts (mid-2000s TXT 48 and all RXV models), the 51V 105Ah Fleet Lithium battery is a popular drop-in solution. It matches the 48V system (51.2V nominal) and provides ~35+ miles per charge in a standard two-seat cart – roughly double the range of stock lead-acid batteries. This 105Ah pack is recommended for most stock or mildly upgraded E-Z-GOs, offering a great balance of range and performance. Enthusiasts with modified carts (rear seats, lift kits, or torque motors) may opt for the 51V 160Ah “Long Range” pack, which boosts runtime up to ~60 miles and can deliver higher sustained current for demanding setups. The 160Ah pack’s greater capacity and robust BMS (250A continuous output) ensure that even high-torque controller upgrades (e.g. Navitas kits) get the amperage they need for strong acceleration and hill-climbing without voltage sag. Both 51V models are fully compatible with the cart’s 48V wiring and accessories, requiring only the included lithium charger for optimal charging.

- 72V High-Performance Models (E-Z-GO 72V Freedom & Express): E-Z-GO introduced 72V models in the 2010s to achieve higher speed and power. Fleet Lithium’s 76V packs (nominal ~76.8V) are made for these high-voltage carts. A single 76V 105Ah pack can replace the eight lead-acid batteries in a 72V cart, offering ~70+ miles of range in light-duty use. For maximum range and performance on 72V systems, the 76V 150Ah NexGen pack is ideal – it’s a high-output battery capable of ~70 miles per charge in heavy carts and designed for dual-motor 4x4 vehicles or hunting buggies that demand extra capacity. These 72V lithium upgrades not only extend range but also maintain higher voltage under load, meaning less speed drop-off on hills compared to lead. Even older dual-pack setups (like Bad Boy Buggies with dual 36V systems) can be simplified by converting to a single 76V Fleet Lithium pack for easier maintenance and improved reliability.

Club Car Golf Carts (48V Systems)

- Club Car DS (2000–2005, 48V): The 48V DS models can directly use Fleet Lithium’s 51V 105Ah battery for a dramatic performance upgrade. In these classic carts, one 51V pack replaces four 12V or six 8V lead batteries, freeing up weight and space. Expect roughly 30–35 miles per charge with the 105Ah pack in a two-passenger DS. The lighter weight (about half the weight of the original batteries) improves acceleration and reduces strain on the frame. For DS carts with a rear seat or high-speed motor, the 51V 160Ah pack is a prudent choice – its larger capacity supports the higher load and maintains range (~55–60 miles) even with extra passengers.

- Club Car Precedent / Tempo / Onward (2004–Present, 48V): All modern 48V Club Car models (including the Precedent, its fleet variant Tempo, and the consumer Onward) are ideal candidates for Fleet Lithium’s 51V systems. The 51V 105Ah is usually sufficient for golf or neighborhood use, delivering about 35–40 miles per charge in a Precedent. It fits neatly in the Precedent’s battery bucket once the old batteries are removed – yielding huge weight savings and no more acid spills. For high-demand applications (e.g. a lifted Onward with larger tires, or a 4–6 passenger limo cart), the 51V 160Ah pack is recommended. Its greater amp-hour reserve and higher discharge capability ensure strong performance even when hauling a full load or using power-hungry accessories. In a lifted or six-seater Club Car, the 160Ah can provide upwards of 55–60 miles of range while supplying the heavy current that these modified carts require. (Both Fleet Lithium packs output ~51V nominal and connect to the stock solenoid and controller just like the original batteries.)

- Club Car OEM Lithium Models: In recent years Club Car has offered factory lithium-ion options (e.g. the Onward HP Li-Ion, or fleet models with LG Chem battery packs). These systems use CAN-bus communication between the battery, controller, and vehicle control module. Fleet Lithium’s NexGen BMS is designed to replace these OEM packs seamlessly – it can communicate via CAN to mimic the messages the cart expects. For example, a Fleet Lithium 51V pack can be configured to work with a Club Car that came with an OEM CAN-enabled lithium battery, often with no drivetrain modifications. The benefit of upgrading is a significantly higher capacity pack with heated cells – meaning a Club Car that came factory lithium can now handle cold weather better (the stock pack lacked heating). In summary, any 48V Club Car from the oldest DS to the latest Onward can be converted to Fleet Lithium, bringing longer range and the peace of mind of an American-engineered system.

Yamaha Golf Carts (48V & 36V)

- Yamaha G-Series (G16/G19/G22): Late-90s and early-2000s Yamaha electric models spanned 36V and 48V systems. The G16 (1996–2001) was a 36V cart – upgrading it is as simple as installing a Fleet Lithium 36V 105Ah pack in place of the six 6V lead batteries. This yields a major weight reduction and longer drive time while maintaining the required 36-volt supply. Models like the G19 (48V with regen braking) and G22 (48V) should use the 51V 105Ah pack as a drop-in replacement. Because these Yamaha models often had regenerative braking, Fleet Lithium’s BMS is built to handle regen currents safely – protecting the battery from over-voltage during braking. The lithium upgrade also eliminates the voltage sag common in those older carts, resulting in smoother acceleration uphill and more consistent speed.

- Yamaha Drive (G29) & Drive2 (2007–Present, 48V): Modern Yamaha carts (Drive and Drive2) are 48V and typically use four 12V batteries (in the Drive) or six 8V batteries (in the Drive2 AC models). Replacing these with a 51V Fleet Lithium pack is a straightforward upgrade. Drive/Drive2 owners can expect roughly 30–40 miles of range with the 105Ah pack in normal use, and significantly improved throttle response because the lithium battery can supply high current with minimal voltage drop. For Drive-series carts that have rear seat kits, lift kits, or high-speed motors, choosing the 51V 160Ah pack ensures ample capacity and performance overhead. The larger pack can deliver the sustained amperage that Yamaha’s high-power AC motors (in the Drive2 AC models) demand. Fleet Lithium’s BMS is compatible with Yamaha’s stock controllers as well as popular aftermarket controllers (Navitas, Alltrax), so integration is smooth.

- Yamaha OEM Lithium (Drive2 PowerTech Li): Yamaha’s latest Drive2 PowerTech Li models come factory-equipped with a RoyPow® lithium battery system. While those perform adequately, they are limited (~105Ah capacity) and have known cold-weather limitations (the Yamaha/RoyPow pack lacks an active heating system). Fleet Lithium offers a compelling upgrade path: you can replace the RoyPow/Yamaha battery with a 51V Fleet Lithium pack to gain more capacity and better cold-climate performance. The swap is typically plug-and-play because the Fleet battery can be configured to work with Yamaha’s controller signals. In essence, any Yamaha from the G-series through the newest Drive2 can be retrofitted with Fleet Lithium – bringing the cart to the forefront of battery technology.

Utility & 4x4 Vehicles

- 48V Utility Carts (Cushman, Carryall, Gator, etc.): Many utility and industrial electric vehicles (Cushman Hauler 48V, Club Car Carryall, Yamaha UMAX, even the 48V John Deere Gator) can be upgraded with Fleet Lithium. For these work-oriented carts, the 51V 160Ah “Long Range” pack provides roughly 50+ miles of runtime and delivers stable voltage under heavy load – perfect for hauling or farm use where range and torque are critical.

- High-Voltage LSVs & Off-Road 72V Carts: Some street-legal Low Speed Vehicles (e.g. Epic carts) and 4x4 off-road carts run on 64V or 72V systems for extra speed and power. Fleet’s 76V lithium packs allow these vehicles to consolidate complex multi-battery setups into a single high-output unit. The 76V 150Ah NexGen pack, in particular, is perfectly suited for high-voltage conversions – it delivers up to ~70 miles per charge and handles the demands of dual-motor drives and high-torque 72V controllers.

No matter the make or model – from a 30-year-old 36V golf buggy to a cutting-edge 72V utility cart – Fleet Lithium has a compatible battery solution.

Fleet Lithium Battery Specs

Each Fleet Lithium battery pack is built with advanced technology. The table below highlights key specifications of our most popular models, and we explain afterward how these specs translate into real-world performance improvements.

| Battery Model | Nominal Voltage | Capacity (Ah) | Max Continuous Discharge | Peak Discharge | Approx. Weight | Dimensions (L×W×H) |

|---|---|---|---|---|---|---|

| 36V 105Ah (High Output) | 38.4 V (for 36V carts) | 105 Ah | 105 A | 150 A | ~35 lbs | 13.2″ × 6.7″ × 8.5″ |

| 48V 105Ah (51V Nominal) | 51.2 V (for 48V carts) | 105 Ah | ~100–105 A (est.) | ~150 A | ~90–100 lbs | ~13″ × 12″ × 10″ |

| 48V 160Ah (51V “Long Range”) | 51.2 V (for 48V carts) | 160 Ah | 250 A | 600 A | 136 lbs | 20.1″ × 14.2″ × 9.2″ |

| 72V 105Ah (76V High Output) | 76.8 V (for 72V carts) | 105 Ah | ~100–150 A (est.) | ~200–300 A (est.) | ~100 lbs | ~13″ × 12″ × 10″ (approx.) |

| 72V 150Ah (76V NexGen) | 76.8 V (for 72V carts) | 150 Ah | ~250–300 A (est.) | ~600+ A (est.) | ~140 lbs | Larger form factor (for high-capacity conversions) |

Note: All Fleet Lithium batteries use safe Lithium Iron Phosphate (LiFePO4) chemistry and include the advanced “NexGen” BMS with built-in safety features (e.g. overheat, overcharge, and short-circuit protection).

Voltage: Fleet Lithium batteries are built to the correct nominal voltages for golf carts (approximately 38V for “36V” carts, 51V for “48V” carts, and 76V for “72V” carts). This ensures compatibility with stock controllers and motors – your cart sees the expected voltage, just with a much flatter discharge curve. In practical terms, a lithium battery stays near its nominal voltage for most of the discharge, whereas a lead-acid pack’s voltage drops steadily. The result is higher average voltage during operation, meaning brighter lights, stronger accessories, and often a slight bump in top speed. (For example, a 48V cart with a Fleet Lithium 51.2V pack might run ~2 MPH faster in situations where a lead pack would have started to sag, since the lithium remains in the 50+V range until nearly empty.)

Capacity (Ah) & Energy (Wh): Amp-hours indicate the battery’s fuel tank size, and Fleet Lithium offers large capacities (105Ah, 150Ah, 160Ah) relative to typical golf cart needs. For instance, a 105Ah LiFePO4 pack at ~51V stores about 5.4 kWh of energy, and a 160Ah pack stores ~8.1 kWh – significantly more usable energy than a set of new lead-acid batteries (which might only deliver ~4–5 kWh usable in a 48V system). This directly translates to extended driving range. A ~105Ah lithium pack can yield roughly 30–40 miles per charge, while a ~150–160Ah pack can approach 60 miles in efficient carts. Importantly, LiFePO4 batteries can be routinely discharged 80–90% without harming longevity, whereas pulling a lead battery that low would severely shorten its life. In other words, nearly all of the lithium battery’s advertised capacity is usable on a daily basis.

Weight & Size: Fleet Lithium batteries dramatically cut the weight of your cart’s battery system. For example, a 48V 105Ah pack weighs around 90–100 lbs (depending on the exact enclosure), compared to ~300 lbs for the six 8V lead-acid batteries it replaces – about a 70% weight reduction. The difference is even more pronounced with higher capacity packs: even the largest 160Ah lithium pack is ~136 lbs, still far lighter than the 400+ lbs of lead batteries that would be needed for similar range. This huge weight savings translates into faster acceleration and improved hill-climbing for the cart, since there’s much less mass slowing the vehicle down.

Fleet Lithium 51V 105Ah Battery – Highlights:

- Nominal Voltage: 51.2 V (drop-in replacement for any 48V cart system)

- Capacity: 105 Ah (~5.4 kWh of usable energy storage)

- Weight: ~90 lbs (replaces ~300 lbs worth of lead-acid batteries)

- Typical Range: ~30–40 miles per charge (in a 2-seat golf cart on flat terrain)

- Max Continuous Discharge: ~100 A (supports stock controllers and moderate upgrades)

- Maintenance: Zero maintenance (sealed battery with integrated BMS – no watering or cleaning terminals)

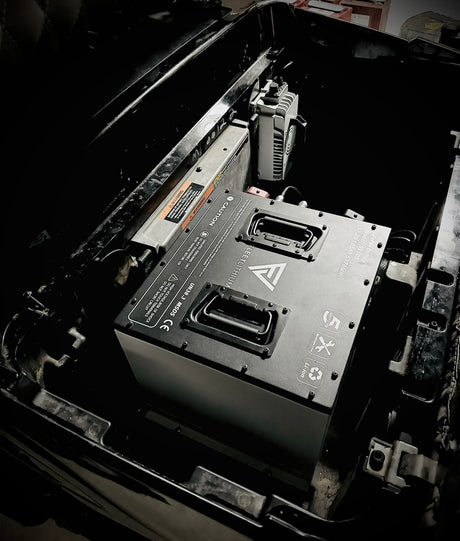

Fleet Lithium 76V 150Ah “NexGen” Battery – Highlights:

- Nominal Voltage: 76.8 V (for high-performance 72V carts and vehicles)

- Capacity: 150 Ah (over 11 kWh of energy for maximum range)

- Weight: ~140 lbs (still much lighter than equivalent lead battery banks)

- Typical Range: ~60–70 miles per charge (in efficient carts or LSVs, depending on configuration)

- Max Continuous Discharge: ~250 A (handles high-power dual-motor setups; ~600 A peak output)

- Features: NexGen BMS with built-in heaters for cold weather, CAN-bus integration for smart controllers, and a built-in fire suppression system for safety

Installation Tips

Installing a Fleet Lithium battery is straightforward and generally plug-and-play. Here are some tips to ensure a safe, clean installation:

- Preparation: Switch the cart’s run/tow switch to “Tow” (if equipped) and turn off the ignition key before beginning. Remove the old lead-acid batteries (carefully disconnecting cables, starting with the negative). Clean any corrosion in the battery bay so you have a fresh start for the new pack.

- Mounting: Place the Fleet Lithium battery in the cart’s battery compartment using the supplied brackets or mounting plate (if required for your model). The lithium pack is much smaller and lighter, so use the bracket or included hardware to secure it firmly (no shifting during driving). Ensure all mounting bolts are tight and the pack is stable.

- Wiring: Connect the new battery’s positive and negative terminals to the cart’s main + and – cables (the same connections the old pack used). Fleet Lithium packs come with high-quality cables and terminal hardware to make this easy. Double-check that all connections are tight (use insulated tools and take care not to short the terminals). Typically, the battery terminals are studs – tighten the nuts to spec (around 10–12 N·m, per manual) but do not over-tighten.

- Charging System: Install the new lithium charger that comes with the battery pack (a 51V charger for 48V packs, or a 76V charger for 72V packs). This charger can be mounted onboard the cart or used as an off-board unit. Many Fleet Lithium kits include a new charging receptacle that fits in the original charge port hole, or a quick-connect harness (e.g. an Anderson plug) that attaches to the battery for easy charging. Do not reuse the old lead-acid charger – lithium batteries require the proper charger profile. The Fleet charger will automatically shut off when the battery is full, and there’s no need for an onboard computer (OBC) to control charging.

- Club Car OBC Bypass: In older Club Car models with an Onboard Computer (OBC), you will need to bypass or remove the OBC when installing the lithium pack and charger. The OBC was used for controlling lead-acid charging and is not needed (and can interfere) with the new lithium system. Fleet Lithium provides instructions for bypassing the OBC (usually a simple wiring change). Once bypassed, the new lithium charger plugs directly into the battery.

- Post-Installation Check: After securing the battery and hooking everything up, double-check all connections and turn the cart’s run/tow switch back to “Run.” Turn the key on and verify the cart powers up normally. If the cart has a battery gauge on the dash, verify it reads correctly for the new battery (Fleet Lithium often supplies a new SOC meter or a Bluetooth app to monitor charge). Take the cart for a short test drive to ensure smooth operation. You should immediately notice better acceleration and no voltage sag on hills. Once everything checks out, secure any loose wiring with zip ties and enjoy your upgraded cart.

- No Maintenance: Going forward, maintenance is minimal – no more adding water or cleaning acid corrosion. Fleet Lithium batteries are sealed and require no routine upkeep. It’s a good idea to occasionally inspect cable tightness and keep the battery area clean, but unlike lead-acid packs, a lithium pack will not need constant attention. Many installers report that after a quick test drive, there’s little else to do except maybe show the cart owner the new Bluetooth monitoring app. The lithium upgrade makes ownership easier and worry-free.

Follow the detailed installation manual provided with your battery for any model-specific steps. A proper install will look factory-clean and ensure your new battery delivers optimal performance and longevity.

Fleet vs. Competitors

The lithium golf cart battery market includes a few major players (like EcoBattery, RoyPow, and Allied Lithium). Here’s how Fleet Lithium compares, focusing on features and performance rather than price:

EcoBattery - (Updated 9/16/25: See note at bottom)

- Cold Weather: EcoBattery packs lack internal heating, meaning they cannot charge (and may have reduced output) in freezing temperatures. Fleet Lithium’s NexGen batteries have built-in heaters, so you can charge and drive even in sub-freezing conditions. This is a clear advantage for Fleet Lithium in any cold climate.

- Expansion & Integration: To run EcoBattery packs in parallel, an external kit is required, and their system offers only basic Bluetooth monitoring. Fleet Lithium packs are designed for easy expansion without extra hardware – if you ever needed to parallel batteries, the BMS handles it. Moreover, Fleet’s BMS supports CAN bus communication, allowing deep integration with cart controllers and diagnostic systems (useful for advanced users or fleet management).

- Overall Approach: EcoBattery focuses on simple drop-in functionality, whereas Fleet Lithium emphasizes advanced technology integration. Fleet’s approach (with features like self-heating and CAN connectivity) yields a more resilient battery solution that performs consistently year-round and provides richer data/diagnostics than an EcoBattery setup.

RoyPow

- Controller Integration: RoyPow (a China-based brand) supplies lithium packs that are largely “universal” and plug-and-play, often bundled with extras like a voltmeter or DC converter. However, RoyPow batteries have minimal support for communicating with the cart’s controller (little to no CAN bus integration). Fleet Lithium’s American-engineered BMS is built for seamless communication with OEM and aftermarket controllers (Navitas, Curtis, etc.), which means the battery can share data or safety signals as needed. This deep integration is one reason many OEMs and custom builders partner with Fleet Lithium for high-end builds.

- Cold Weather: Only some newer RoyPow models offer internal heating, and those are usually optional or higher-cost versions. Every Fleet Lithium NexGen pack includes an active heating system as a standard feature. That means Fleet batteries are ready for year-round use in any environment, whereas a standard RoyPow might struggle or shut off in below-freezing weather.

- Build Quality & Safety: Fleet Lithium prioritizes robust design and safety. For example, Fleet packs incorporate a built-in fire suppression agent, heavy-duty MOSFETs and wiring, and conformal-coated electronics to protect against moisture and vibration. RoyPow’s packs are reliable for general use, but they don’t publicize the same level of ruggedization or safety features. Fleet’s focus is on critical quality factors (cell balancing, thermal management, fail-safes) rather than adding flashy extras.

- Support & Warranty: Fleet Lithium is a U.S.-owned company with customer support and engineering based in the USA. RoyPow, while it has a U.S. distribution presence, is a Chinese company at its core. Some customers prefer the peace of mind of domestic support – it can mean faster service, easier communication, and products designed with U.S. regulatory standards in mind. Both companies offer warranties, but Fleet’s local support network often makes the service process smoother if issues arise.

Allied Lithium

- Modular vs. Single Pack: Allied Lithium often sells multiple smaller batteries (e.g. 12V units in series) to replace a cart’s pack, or they offer a set of two 48V batteries to increase capacity. This modular approach can simplify initial installation (you can use some existing wiring), but it also introduces more points of connection and potential imbalance. Fleet Lithium uses a single-pack solution (one battery with one BMS) for each cart voltage. This “one big battery” philosophy means simpler wiring, less chance of connection failure, and a BMS that manages all cells together for optimal balance.

- Discharge Performance: Allied’s BMS and cell configuration typically allow a lower continuous discharge current (often suitable for stock carts but not heavy upgrades). In high-demand scenarios (say, a lifted 6-passenger cart climbing a hill), an Allied setup might hit its output limits or see voltage sag as the batteries struggle to share the load. Fleet Lithium’s packs are built for high output – hundreds of amps continuous – so even under heavy loads, the voltage stays stable and the BMS won’t cut out. This is a critical difference for performance enthusiasts or commercial users who push their vehicles to the max.

- Scalability & Complexity: Allied Lithium sometimes promotes adding extra batteries to extend range (e.g. dropping in another 48V module for more Ah). While this can work, it adds complexity: more cables, and the individual BMS units in each battery don’t communicate with each other. The result can be uneven charging or one pack working harder than the other. Fleet Lithium’s view is that one appropriately-sized pack should handle the job (though Fleet packs can also be paralleled if absolutely needed). By avoiding multi-pack setups, Fleet reduces potential failure points and makes the system more foolproof.

- Features & Monitoring: Like EcoBattery, Allied’s standard packs lack self-heating and offer only basic monitoring (some models have a simple Bluetooth voltage meter or SOC indicator). Fleet Lithium includes advanced features on all packs: automatic cell heating for cold weather, and a comprehensive Bluetooth app that shows state-of-charge, voltage, current, and even diagnostic fault codes. In essence, Allied provides a convenient entry-level lithium solution using a “mix-and-match” approach with existing components, whereas Fleet Lithium delivers a next-level, integrated solution with maximum performance, safety, and intelligence.

Bottom Line: Fleet Lithium distinguishes itself from competitors with its blend of advanced technology (smart BMS with CAN, self-heating, high-output design) and an uncompromising focus on safety and reliability. It’s a lithium upgrade engineered to feel like a factory-installed system – delivering superior performance, longer lifespan, and worry-free operation for your golf cart or utility vehicle.

Eco Battery "Self-Heating Gen 3" Possible Fire Hazard, and Safety Concerns – Updated 9/16/2025

Exactly 120 days ago, this article called out Eco Battery’s lack of heated battery technology—pretty bluntly. Today—almost to the hour—they’ve announced their new “self-heating” battery. The timing isn’t coincidence. It takes 90–100 days for containers to arrive from China, which makes it clear: they read the article, placed an order, and rushed product to market. Not R&D—just reaction.

If Eco’s heated battery has caught your eye, be careful—you don’t want to be the one discovering its flaws. Our NexGen batteries are tested, proven, and built with redundant safeguards to perform reliably in freezing conditions. Safety isn’t something we gamble on, and neither should you.